TECHNICAL DATA

- Max. Operating Temperature: 70°C

- Min. Bending Radius: 10 x cable Ø

- Production Standards: EN 60794-3-12

INTRODUCTION

These cables are used in direct burial, telephone exchanges and subscriber distributions. These cables having 0.4 and 0.5 mm conductor diameter are used for distribution network and 0.6, 0.63, 0.65, 0.8 and 0.9 mm conductor diameter are used for long distance network.

CODE of CABLE

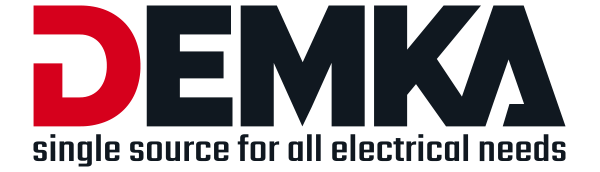

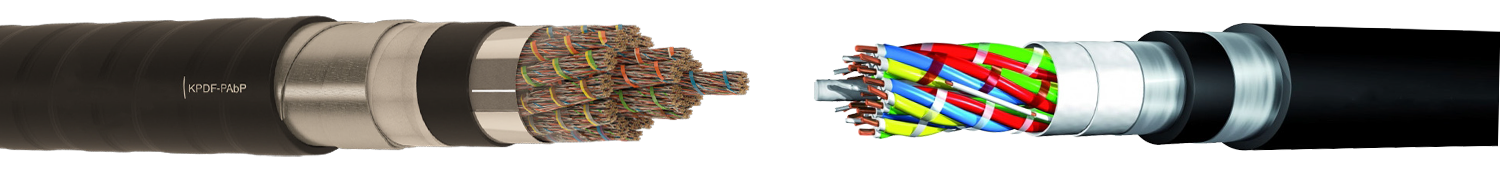

- KPDF-PAbP – PDF-PAbP; A-02YSF(L)2Yb2Y – A-2YF2Y(L)b2Y

CONSTRUCTION

- Conductor: Electrolytic annealed solid copper

- Insulation: Color coded foam skin polyethylene cladded with solid polyethylene or solid polyethylene insulation

(BS 6234 Type 03 – ASTM D 1248) - Stranding: Star quads or pairs, each having special lay length to minimize the crosstalk and capacitance unbalance, are assembled into 10 pairs units. Groups having 25, 50 or 100 pairs are stranded together into cable core

- Filling Compound: Cable core is filled with a special jelly filling compound to avoid the water leakage into air spaces

- Wrapping: A non-hygroscopic and dielectric polyester tape is applied on the cable core longitudinally or helically

- Filling Compound: Secondary jelly filling is applied between wrapping and screen in order to provide water proofness

- Screen: Both sides are coated with copolymer coated flat aluminium tape over cable core longitudinally for screening

- Inner Jacket: Linear low-density or medium-density, UV resistant black polyethylene outer jacket (ASTM D 1248)

- Filling Compound: Water-swellable tape or filling compund

(Jelly) is applied between inner jacket and armour in order to have water proofness - Armour: Two helically laid galvanized steel tape is applied to increase the mechanical resistance of the cable

- Outer Jacket: Linear low-density or medium-density,

UV resistant black polyethylene outer jacket (ASTM D 1248)